Massive Network Capacity

Instantly access the production capacity of over 5,000 manufacturers with wide ranging capabilities and certificationsacross 46 states and around the world.From your desktop, Strict NDA agreementswith our network protect your privacy.

Instant Quoting Engine

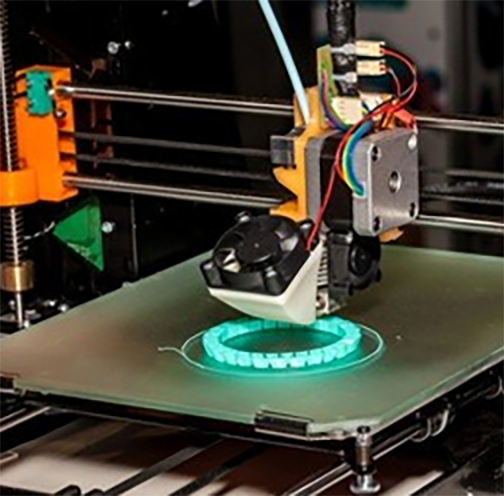

Get DFM feedback, lead times, and pricingin a matter of clicks, not days.MIC-ZG puts Data Science to work for you so youcan easily choose the optimal price/leadtime option for your project.Compatiblewith STEP, Mesh, Parasolid, and ACIS files.

Guaranteed Quality

We are ISO 9001:2015 and AS9100D certified, ITAR registered, and offer CoCs, material certifications, material and process lot traceability, full dimensional reports, inspection reports, and hardware certs. See more details about our Quality Assurance capabilities here.

Top Consumer Product Applications

Prototype Design

Trestles, Chassis and Brackets for Manufacturing

A Variety of Fixtures and Jigs

Metal Case

Plastic Packaging Shell

Cooperative Company Scope:

CCC Manufacturers

Sports Equipment Manufacturers

Toy Manufacturers

Hardware Manufacturers

Commodity Manufacturers

Food Packing Companies

Alcohol and Beverage Companies

Home Appliance Manufacturers

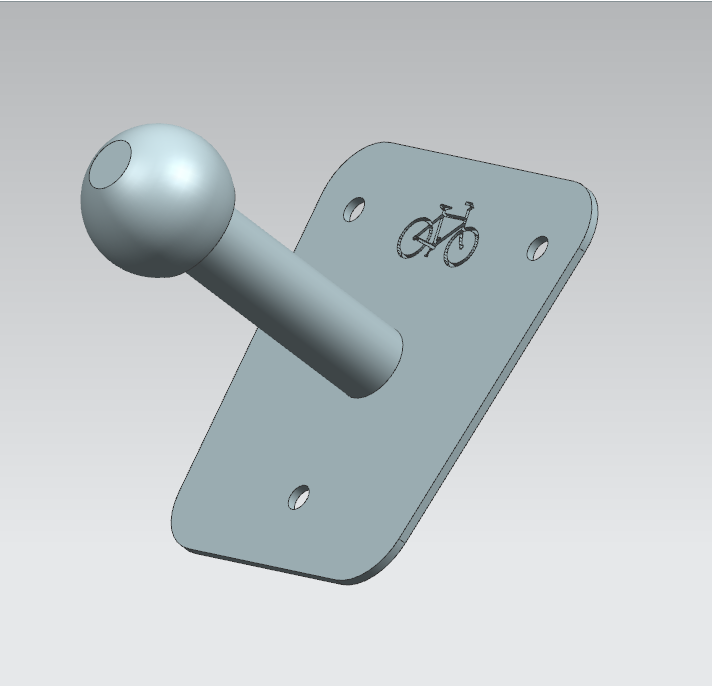

Design

On the premise of meeting the load-bearing requirements, save as much space as possible

Simple shape, easy to install, easy to disassemble

Ball head design, high safety factor

Parts matching: internal expansion screw

Laser Cutting Process (Pattern Engraving)

Laser beam heating is used to perform high-speed, controlled cutting on metal materials that are easily damaged by heat. The main content of this cutting process is that the laser beam heats a small area of brittle material, causing large thermal gradients and severe mechanical deformation in this area, resulting in the formation of cracks in the material.

The laser beam can direct cracks in any desired direction as long as a uniform heating gradient is maintained.

Plastic Spray

1.Sanding: removes oil, rust, welding slag, burrs, and other contaminants from the workpiece.

2.Plastic Spray: The paint is sprayed onto the surface of the workpiece under the operation of an electric field, and the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating; the powder coating is then baked at a high temperature. The plastic particles will be melt, forming a dense final protective layer of varied effects after leveling and curing, firmly adhering to the workpiece's surface.

Sheet Metal Quality Inspection

MIC-ZG has strict requirements on the quality of sheet metal parts:

We strictly check the size according to the drawings.

We strictly check the appearance quality, repair or scrap those that do not match the size without scratching the appearance.

We test the color difference, corrosion resistance, adhesion and other parameters after spraying.

In this way, we optimize product parameters and control errors.

MIC-ZG Manufacturing Capabilities

Sheet Metal Manufacturing Process

Manufacturing Process From creating custom designs to manufacturing, we have the expertise to help you turn your ideas into reality.

Custom laser cutting services

Custom sheet metal parts engineering and manufacturing services from prototyping to mass production. Low cost sheet metal processing solutions from China.

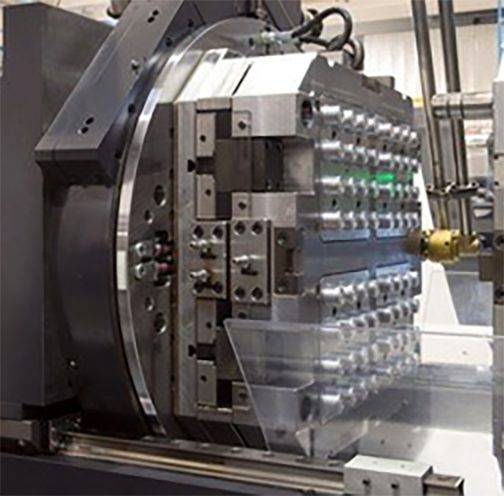

Plastic Molding And Processing

MIC-ZG is an international OEM manufacturer. We are ready for factory audits and video calls at any time.

Online CNC Machining Services

To Get Real-time CNC Machining Quotation for Custom Machined Parts. Precision CNC machining services for prototyping and production.

Industries We Service