$15,000.00 - $35,000.00/ Set |

1 Set/Sets(Min. Order)

Customization:Customized logo(Min. Order: 200 Sets)

Customized logo(Min. Order: 200 Sets)

Graphic customization(Min. Order: 200 Sets)

Shipping: Support Express · Sea freight · Land freight · Air freight

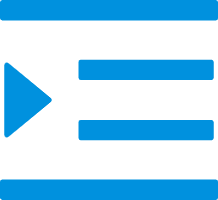

1. Material Preparation

Remove excess material from a material, for example by cutting off excess stock or sanding

2. Machine Setup

Adjust the output of the laser, the distance between the machine and the material, and the speed of the blade

3. Material cutting

Material cutting involves actually moving the blade to cut through the material.

Laser Cutting Service is available for a variety of materials, depending on the type of laser cutting machine used. These materials include wood, plastic, metal, and more.

There are many benefits to choosing Laser Cutting Service over other methods:

- Speed: Laser cutting is much faster than other methods, which means you can produce more in less time.

- Precision: Laser cutting is based on precision, which means your product will be precise down to the smallest detail.

- Eco-friendly: It does not produce any harmful fumes or waste like other methods.

The application range of Laser Cutting Service can be divided into two categories: small and large. Small-scale applications include making parts for products such as jewelry, watches, and cell phones. Large-scale applications include the production of parts for aircraft, automobiles, and spacecraft.

Laser Cutting Service is a process that uses a laser beam to cut precise, consistent shapes from the material. This is a particularly advantageous process for making precision parts and products because the laser can pass through the material with little deformation or tearing.

What types of Laser Cutting Service are there?

Laser Cutting Service is mainly divided into three types: digital, laser beam epitaxy (LBE) and metal laser cutting (MLC). Digital laser cutting uses a computer to control the power and movement of the laser beam. Laser beam epitaxy uses high-power light to heat materials until they break down and form new layers. Metal laser cutting uses a very powerful laser to cut metal.

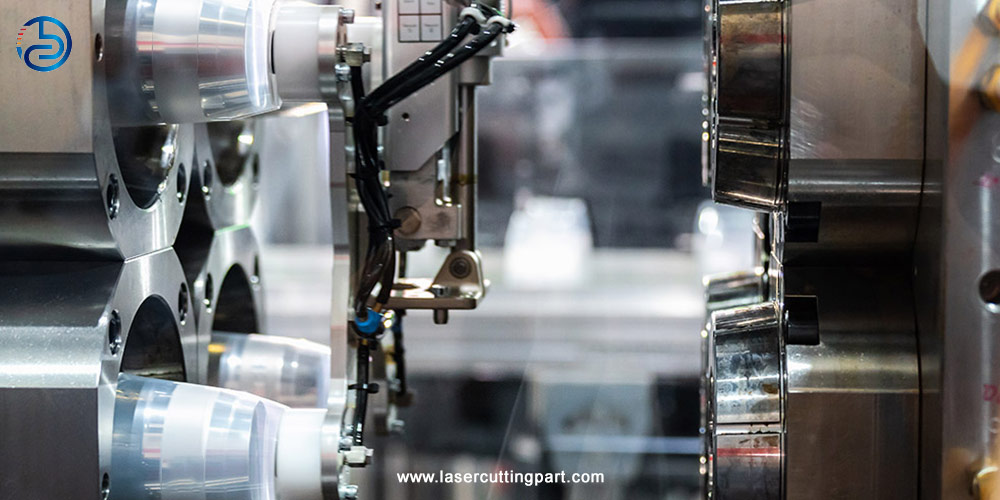

Welcome to our Injection Molding factory! Our goal is to provide you with the best quality injection molded parts, tools and components. We have a team of experienced and knowledgeable engineers and technicians to ensure that your project is completed on time and within budget. Our state-of-the-art facility features the latest in injection molding technology, giving us the capability to produce high-precision products with repeatable accuracy. We take pride in offering a comprehensive range of services including design, prototyping, mold making, and production runs.

We specialize in producing parts from a variety of materials including plastics, metals, and composites. Our engineering team can help you develop your product from concept to completion, no matter how complex your needs may be. We understand that time is precious and we work hard to ensure that our turn-around times are fast and efficient.

Our injection molding services include design, prototyping, production, and finishing. We also offer a wide range of materials for use in your projects, including metals, plastics, and composites. Whether you need a single part or an entire production run, our team is here to make sure you get the perfect product for your needs.

In addition to our injection molding services, we also offer a wide array of secondary operations such as trimming, assembly, painting, and packaging. This allows us to provide complete turn-key solutions for all of your injection molding needs.

At MIC-ZG, we are committed to delivering superior quality products with exceptional customer service. We look forward to working with you on your next injection molding project!

MIC-ZG offers a wide range of injection molding services, including design, prototyping, tooling, production, assembly, and testing. Their team of experienced engineers and technicians use the latest technologies and materials to ensure that every project meets the highest quality standards. Additionally, their in-house tooling and production facilities allow them to produce high-quality parts at competitive prices.

MIC-ZG also provides comprehensive support services such as product design consultation, mold design optimization, material selection advice, troubleshooting guidance, logistics planning and more. Their goal is to provide customers with a complete solution for their injection molding needs.

China has become one of the leading countries in injection molding technology. This technology has enabled China to produce high-quality products at a lower cost than most countries. It involves injecting plastic or other material into a mold to create a desired shape or form. The injection molding process is used to create a wide variety of products from automotive parts to medical equipment.

China Injection molding takes advantage of the unique properties of thermoplastics, which can be heated, shaped and cooled repeatedly without losing their physical characteristics. This makes them ideal for creating intricate shapes and complex designs.

China's injection molding industry is highly advanced and well-established, allowing companies to produce their products quickly and efficiently. They also have access to advanced machines and tools that help them optimize their production lines. With the help of these machines, they are able to reduce production costs while maintaining high quality standards.

The China injection molding industry also has access to a large number of skilled workers who have years of experience in the field. This ensures that each product produced is of the highest quality and meets all international standards. In addition, many China injection molding companies offer custom-design services so that customers can get exactly what they want for

China injection molding technology is an advanced manufacturing process that produces parts from thermoplastic or thermosetting materials. It is a fast, efficient, and cost-effective method that can be used to produce large quantities of parts at high precision with repeatable accuracy. China Injection molding is widely used in the automotive, medical, aerospace, and consumer goods industries.