Wide Application Of Sheet Metal Press

What Is Sheet Metal Press?

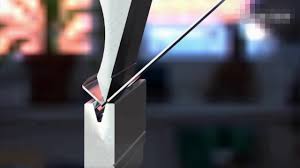

Sheet metal press is a process where a sheet of metal is placed between two dies and then pressure is applied to the dies in order to form the sheet metal into the desired shape. The amount of pressure that is applied depends on the thickness of the sheet metal and the desired final shape.

There are many different types of presses that are available on the market, each designed for a specific purpose. When choosing a press, it is important to consider the type of project you will be working on and what features you need in order to get the job done right.

Maintenance And Cleaning Of Sheet Metal Press

Maintenance and cleaning of a sheet metal press is a process that should be carried out on a regular basis to keep the machine running smoothly and efficiently. There are several things that need to be done in order to properly maintain and clean a sheet metal press, and failing to do so can lead to serious problems down the road.

The first step in maintaining and cleaning a sheet metal press is to make sure that the area around the machine is clean and free of debris. This includes removing any loose pieces of metal, oil, or other materials that could potentially clog or damage the machine.

Once the area around the machine is clean, you will need to inspect all of the moving parts for wear and tear. Look for any signs of excessive wear or damage, and if you find any, replace the parts as soon as possible.

In addition to inspecting the moving parts, you will also need to regularly lubricate them. This will help to keep them running smoothly and prevent them from seizing up.

Finally, you should also regularly check the fluid levels in the machine. If the fluids are low, it could lead to problems with the operation.